RoTechBooster

RoTechBooster

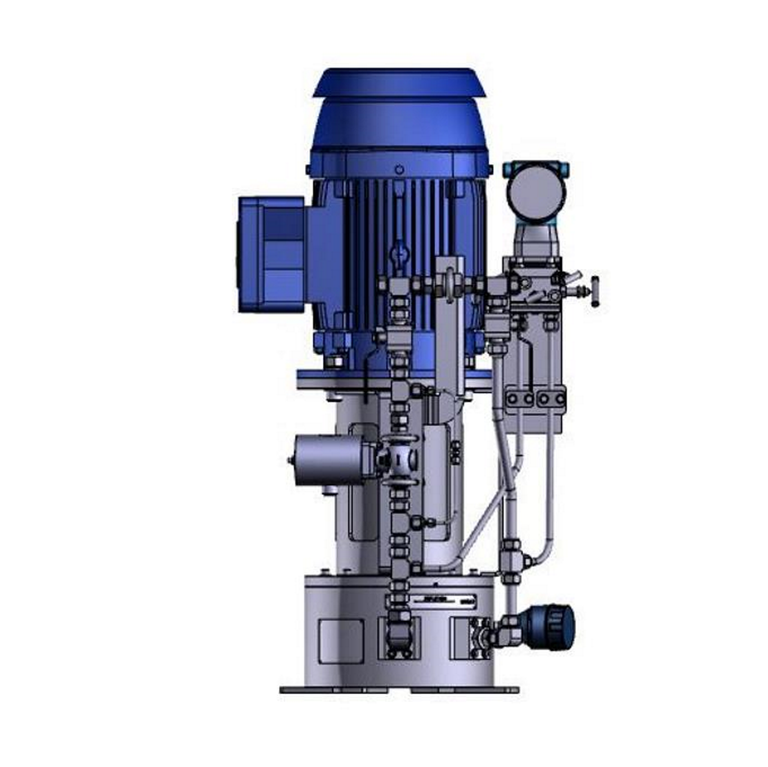

| Item | Description |

| 1.1 | Outer rotor |

| 1.2 | Inner rotor |

| 1.3 | Can / pressure barrier |

| 2 | Motor |

| 3 | Bearing cartridge |

| 4 | Impeller |

| 5 | Pressure housing |

RoTechBooster

Features

- Electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- 24,000 hours of operation before required maintenance

- Various models available, to meet specific requirements

Advantages

The RoTechBooster ensures abundant, reliable, and consistent seal gas flow, through fluctuating operating conditions; thus, clean and dry gas is supplied to the gas seal in every situation.

- Proven experience

- Simple to set-up, easy to operate

- High reliability and availability

- Unlimited continuous operation

- Avoid seal failures

- Low maintenance costs

- Energy efficient

- Eliminates the concern of unreliable external seal gas source

Standards and approvals

Certifications or compliance with NACE, PED, ATEX, API 692 compliant. Offshore certifications and others available upon request.

Recommended applications

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Hydrocarbons

- Compressors using gas seals

Functional description

Adequate, clean, and dry gas flow at the seal governs seal reliability. During normal operation, this is achieved by taking product gas from a high-pressure stage or discharge of the compressor, flowing it through a conditioning system and using it to flush the seal.

When the compressor slows or is at pressurized standstill, gas flow is interrupted and leaves the seal(s) unprotected from contaminated product gas. This poses a serious risk, because unconditioned product gas leaves deposits at the seal, leading to high seal leakage or even seal failure. In order to alleviate this problem, seal gas boosters are utilized to draw gas from the compressor through the conditioning system and deliver clean and dry gas to the seal(s).

The RoTechBooster incorporates an EBNM high efficiency magnetic coupling eliminating the need for an additional mechanical seal. Incorporating a magnetic coupling removes any possible additional system leak paths, eliminates emissions, increases safety for personnel and produces virtually wear free operation. Using a high efficiency design efficiently transfers torque, which delivers higher pressure ratings and reduced operating costs. This coupling design guarantees maximum RoTechBooster availability ensuring abundant seal gas flow through all operating conditions.

Learn more about EBNM high efficiency magnetic couplings

When the compressor slows or is at pressurized standstill, gas flow is interrupted and leaves the seal(s) unprotected from contaminated product gas. This poses a serious risk, because unconditioned product gas leaves deposits at the seal, leading to high seal leakage or even seal failure. In order to alleviate this problem, seal gas boosters are utilized to draw gas from the compressor through the conditioning system and deliver clean and dry gas to the seal(s).

The RoTechBooster incorporates an EBNM high efficiency magnetic coupling eliminating the need for an additional mechanical seal. Incorporating a magnetic coupling removes any possible additional system leak paths, eliminates emissions, increases safety for personnel and produces virtually wear free operation. Using a high efficiency design efficiently transfers torque, which delivers higher pressure ratings and reduced operating costs. This coupling design guarantees maximum RoTechBooster availability ensuring abundant seal gas flow through all operating conditions.

Learn more about EBNM high efficiency magnetic couplings

Product variants

RoTechBooster 155L-120,

optional: 155H-20

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional … 240 bar (3,480 PSI), … 360 bar (5,220 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 355 mm (14”)

Height: 960 mm (38”)

Weight: 215 kg (475 lb)

optional: 155H-20

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional … 240 bar (3,480 PSI), … 360 bar (5,220 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 355 mm (14”)

Height: 960 mm (38”)

Weight: 215 kg (475 lb)

RoTechBooster 180L

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI), 360 bar (5,220 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 410 mm (16”)

Height: 1,120 mm (44”)

Weight: 355 kg (785 lb)

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI), 360 bar (5,220 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 410 mm (16”)

Height: 1,120 mm (44”)

Weight: 355 kg (785 lb)

RoTechBooster 225L-120,

optional: 225H-120

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 410 mm (16”)

Height: 1,120 mm (44”)

Weight: 355 kg (785 lb)

optional: 225H-120

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 410 mm (16”)

Height: 1,120 mm (44”)

Weight: 355 kg (785 lb)

RoTechBooster 275L-120,

optional: 275H-120

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 510 mm (20”)

Height: 1,200 mm (47”)

Weight: 510 kg (1,125 lb)

optional: 275H-120

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI), optional 240 bar (3,480 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 510 mm (20”)

Height: 1,200 mm (47”)

Weight: 510 kg (1,125 lb)

RoTechBooster 330L

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 560 mm (22”)

Height: 1,245 mm (49”)

Weight: 565 kg (1,245 lb)

Higher pressure models are available upon request.

Impeller type: Single stage, regenerative

Speed: 1,200 … 4,200 min-1

Design pressure:

Vacuum … 120 bar (1,740 PSI)

Design temperature: 200 °C (392 °F), optional 250 °C (418 °F)

Motor size: 5.5 kW … 15 kW

Diameter: 560 mm (22”)

Height: 1,245 mm (49”)

Weight: 565 kg (1,245 lb)

Higher pressure models are available upon request.

Similar products

RoTechBooster CX

- Standard model

- Plug-n-play

- Compact, electric driven rotating design

- Hermetically sealed

- Delivers seal gas flow as defined by API 692

- Continuous operation

RoTechBooster LNG300

- Standard model

- High flow for low pressure

- Especially for low pressure refrigerant applications

- Compact, electric driven rotating design

- Hermetically sealed