SeccoLip481

SeccoLip481

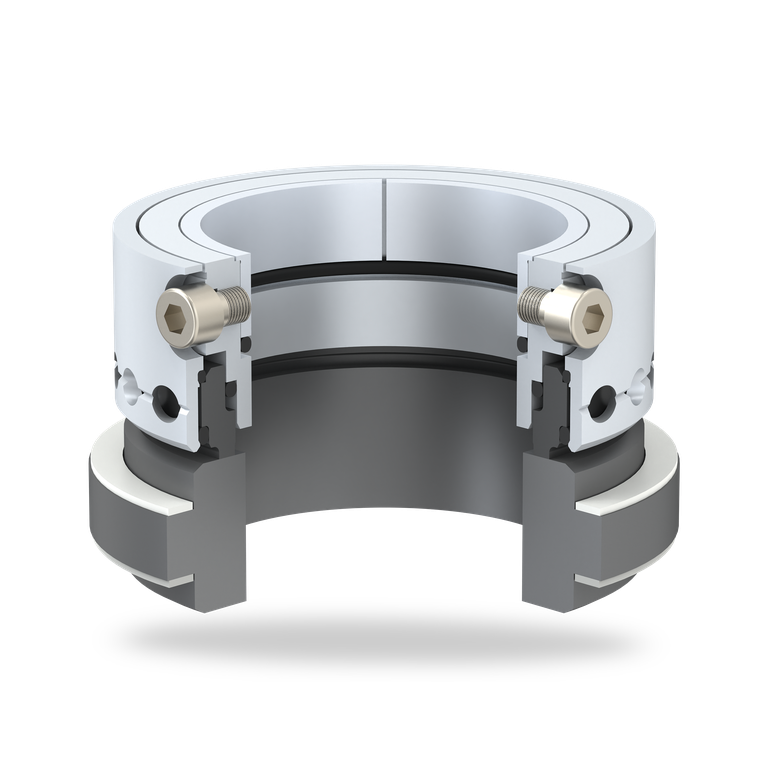

SeccoLip 481L-4

| Item | Description |

| 1 | Lip seal |

| 2 | Inset |

| 3 | Disc |

| 4 | Insert ring |

| 6 | O-Ring |

| 7 | Shaft sleeve |

| 8 | Flange |

| 9 | Housing |

| 13 | Shrink disc |

| 16 | Setting device |

| 23 | Spacer ring |

| 27 | Lip seal |

| 28 | Sliding bearing |

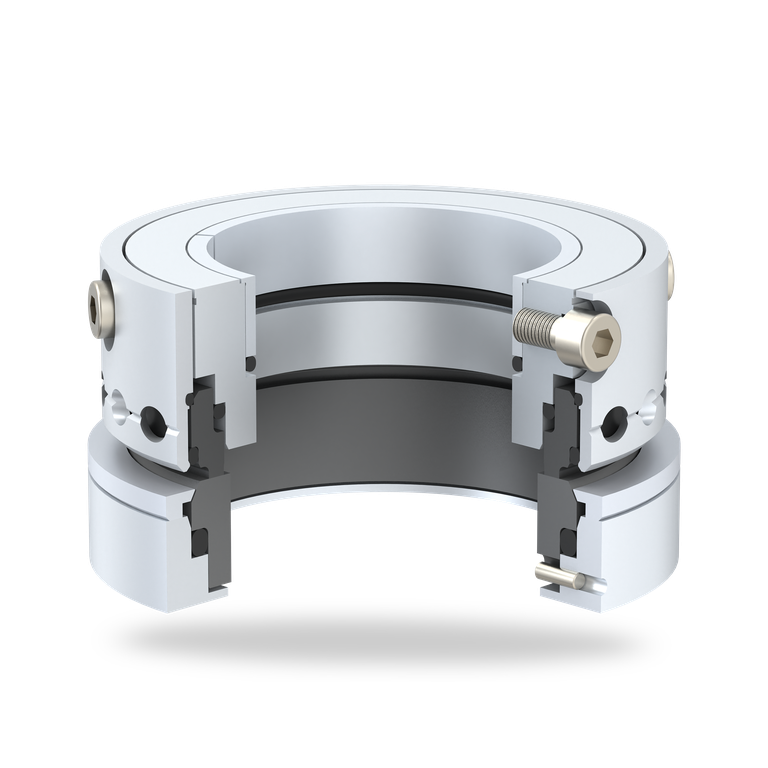

SeccoLip 481-2

| Item | Description |

| 1 | Lip seal |

| 2 | Inset |

| 3 | Disc |

| 4 | Insert ring |

| 6 | O-Ring |

| 7 | Shaft sleeve |

| 8 | Flange |

| 9 | Housing |

| 13 | Shrink disc |

| 16 | Setting device |

SeccoLip481

Features

- For top entry drive;

side drive also available on request - For stainless steel vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

- Cartridge unit

- Variant available for applications with product contact (SeccoLipR)

Advantages

- Available as a ready-to-install cartridge for quick and easy installation

- Tested technology ensures safe use

- Dry-running lip seal - depending on the application no supply system is necessary

- No additional rolling bearing required, but optionally available

- Sealing element made of bright chemically highly resistant PTFE compound

- ATEX type examination certificate available

- CIP/SIP-compatible

- Flush possible

- Available with 2, 3, or 4 sealing lips

- No temperature monitoring required

- Further customer-specific adaptations possible

Materials

Lip sealing element: bright chemically highly resistant PTFE-compound (FDA-compliant)

Secondary seals: FKM (V) Metallic parts: 316L / 1.4404 Other materials are possible, depending on customer requirements.

Secondary seals: FKM (V) Metallic parts: 316L / 1.4404 Other materials are possible, depending on customer requirements.

Standards and approvals

- FDA

- ATEX

- TA-Luft

Recommended applications

- Chemical industry

- Petrochemical industry

- Pharmaceutical industry

- Food industry

- Bulk solids industry

- Agitators

- Mixers

- Reactors

- Dryers

- Screw conveyors

Product variants

SeccoLipR481L-4

This is the low-wear variant designed for demanding applications involving product contact, such as with abrasive and crystalline media. The SeccoLipR®481L features an additional SeccoLipR® component installed on the product side. This protects the PTFE sliding parts and the sealing lips behind it from product ingress.

The SeccoLipR®481L is suitable for top and side drive and is only available with bearings. Flushing can be implemented using a special solution.

| Item | Description |

| 1 | Lip seal |

| 7 | Wave sleeve |

| 8 | Flange |

| 9 | Housing |

| 13 | Shrink disc |

| 16 | Assembly gauge |

| 22 | Roller bearing |

| 45 | SeccoLipR |

SeccoLipR®

The SeccoLipR® component seal, a patented product, is the latest addition to the SeccoLip product range. It is recommended to upgrading to the SeccoLip®481 for use in demanding applications involving abrasive or crystalline media. The upstream metal shield (1) prevents the lip seals behind it from coming into contact with the product. The sliding part (4) adjusts the sealing element in the event of radial shaft deflections and the second PTFE sealing lip (5) provides reliable sealing in vacuum applications.

The SeccoLipR® is also available as a stand-alone solution and can be combined with other EagleBurgmann agitator seals.

The advantages at a glance:

- Protection against product ingress into the seal

- Enables vacuum operation

- Increases reliability and plant availability

| Item | Description |

| 1 | Metal shield |

| 2 | O-ring |

| 3 | PTFE lip seal (product side) |

| 4 | Sliding part |

| 5 | PTFE lip seal (atmospheric side) |

Similar products

SeccoLip461

- For top entry drives, on request for side and bottom entry drives

- For glass-lined vessels

- Dry-running

- Modular and flexible design

- Compensation of shaft deflection by patented technology

- Independent of direction of rotation

- Cartridge unit

SeccoMix 1-E32

- Retrofit for JC Type 32

- Dry-running single seal

- For top entry drives, on request side drive possible

- Balanced

- Multiple springs rotating

- Independent of direction of rotation

- Available in metric and imperial sizes

SeccoMix 1-E32D

- Retrofit for JC Type 32

- Dry-running single seal

- For top entry drives, on request side drive possible

- Balanced

- Outbound

- Multiple springs rotating

- Independent of direction of rotation

- Available in metric and imperial sizes