SMAK

SMAK

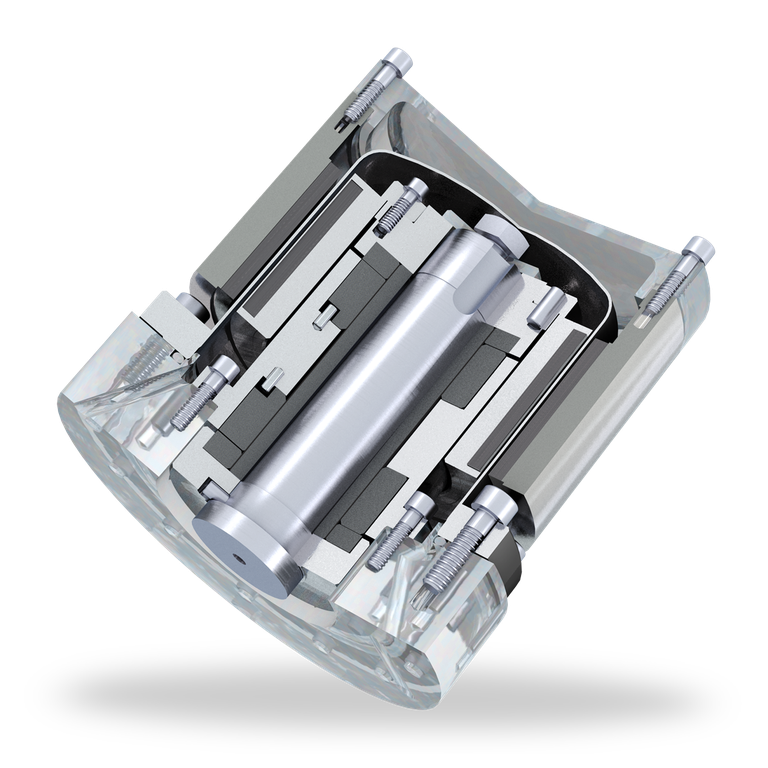

SMAK for bottom drives

| Item | Description |

| 1.1 | Inner rotor |

| 1.2 | Outer rotor |

| 2 | Can |

| 3 | Nut |

| 4 | Bearing bushing |

| 5, 6 | O-Ring |

| 7 | Set screw |

SMAK

Features

Magnetic couplings of the SMAK series are used to transfer torque into mixers and agitators. Top drive, bottom drive or lateral drive. Dangerous or precious media remain isolated in the closed vessel.

Advantages

- Magnetic coupling for mixers and agitators

- Hermetically sealed

- Sterile design

- Parts in contact with the medium are electro-polished

- No contamination by buffer media

- No contact of torque transmitting elements

- No maintenance necessary

- Sliding bearing for bottom drives included

- Speed monitoring optional

- Weld-in or screw-in flanges available

Materials

Sliding bearings: Silicon carbide or zirconia, FDA-compliant

Bearings: Silicon nitride

Magnets: Samarium cobalt

Secondary seals and metal parts according to application and customer's specifications.

Bearings: Silicon nitride

Magnets: Samarium cobalt

Secondary seals and metal parts according to application and customer's specifications.

Standards and approvals

- QHD

- GMP

- FDA

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Chemical industry

- Pharmaceutical industry

- Food processing industry

- Agitators

- Mixers

Functional description

The power transmission occurs contact-free through magnets from the drive shaft to the product wetted output shaft. Between the two rotating parts is the can wich is bolted to the container.

Notes

Top drive coupling with dry running roller bearings available.

Product variants

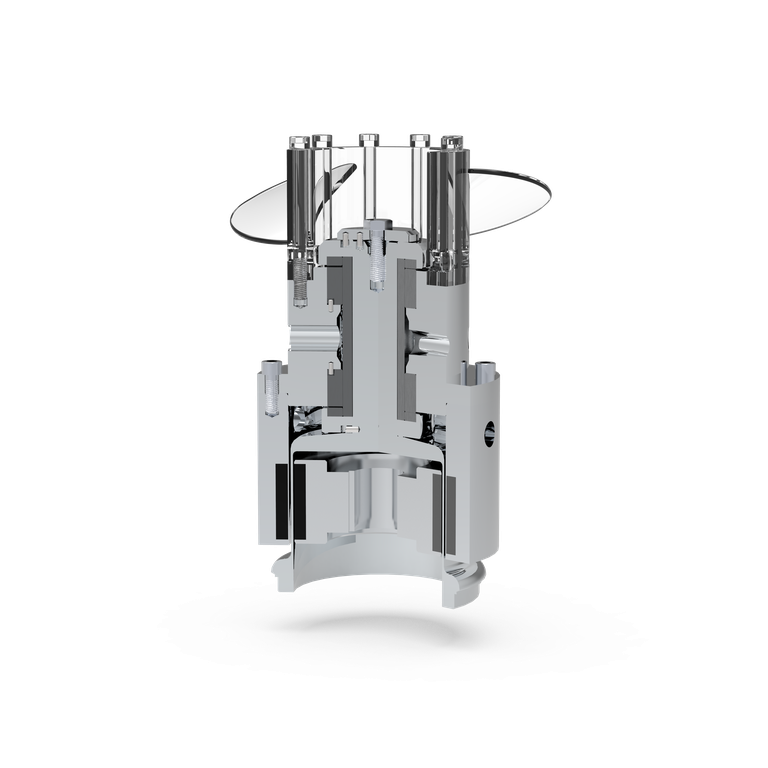

SMAK for top drives

| Item | Description |

| 1.1 | Inner rotor |

| 1.2 | Outer rotor |

| 2 | Motor connection |

| 3 | Can |

| 4, 5 | Bearing |

| 6 | Agitator blade connection |

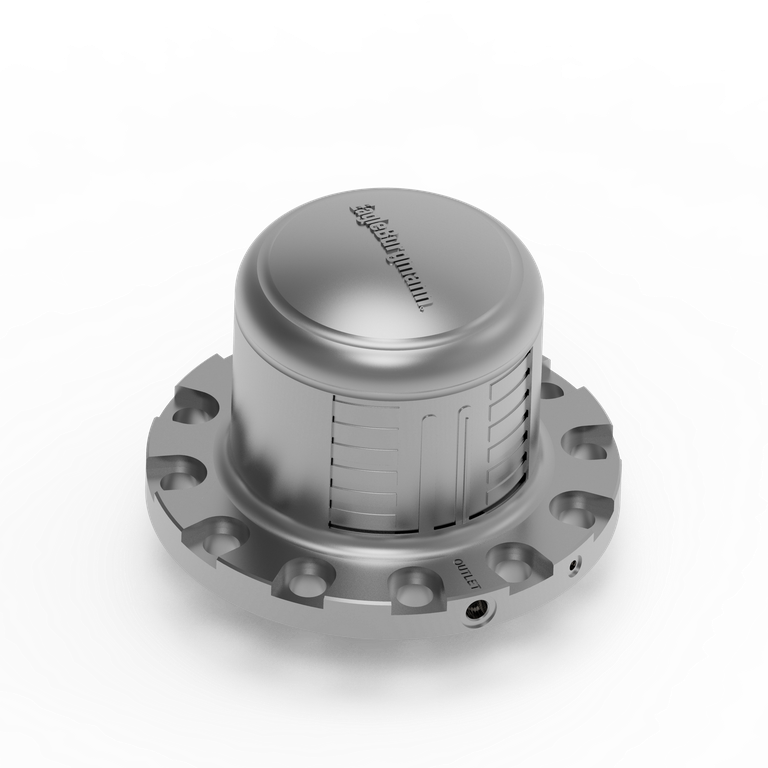

SMAK4-75-4/40

for top drives

Max. torque: 16 Nm

Rotational speed: 0 … 400 min-1

Temperature: (max.) 130 °C (266 °F)

Pressure: 25 bar (363 PSI)

Overall height (agitator element connection to top edge of flange): 340 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

for top drives

Max. torque: 16 Nm

Rotational speed: 0 … 400 min-1

Temperature: (max.) 130 °C (266 °F)

Pressure: 25 bar (363 PSI)

Overall height (agitator element connection to top edge of flange): 340 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

SMAK4-75-6/-40

for top drives

Max. torque: 24 Nm

Rotational speed: 0 … 400 min-1

Temperature (max.) 130 °C (266 °F)

Pressure 25 bar: (363 PSI)

Overall height (agitator element connection to top edge of flange): 360 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

for top drives

Max. torque: 24 Nm

Rotational speed: 0 … 400 min-1

Temperature (max.) 130 °C (266 °F)

Pressure 25 bar: (363 PSI)

Overall height (agitator element connection to top edge of flange): 360 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

SMAK4-135-6/75

for top drives

Max. torque: 100 Nm

Rotational speed: 0 … 400 min-1

Temperature (max.): 130 °C (266 °F)

Pressure. 25 bar (363 PSI)

Overall height (agitator element connection to top edge of flange): 515 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

for top drives

Max. torque: 100 Nm

Rotational speed: 0 … 400 min-1

Temperature (max.): 130 °C (266 °F)

Pressure. 25 bar (363 PSI)

Overall height (agitator element connection to top edge of flange): 515 mm

Diameter (outer magnetic rotor): 110 mm

Materials:

1.4435, EPDM (FDA), Si3N4, PEEK

Surface finish: Ra <0.5

Similar products

eMAK

Magnetic couplings (MAK) are a hermetic, low-maintenance sealing solution for pumps, agitators, and aerators. Dangerous or precious media remains isolated in the closed system circuit. In turn, nothing penetrates to contaminate the medium.

- For standard applications up to 25 bar

- Available from stock

- Single-walled can

- Product-lubricated sliding bearing included (optional)

- High performing

- Energy efficient

- Highly reliable and maintenance-free

RMAK

Magnetic couplings (MAK) are a hermetic, low-maintenance sealing solution for pumps, agitators, and aerators. Dangerous or precious media remains isolated in the closed system circuit. In turn, nothing penetrates to contaminate the medium.

- For agitators and mixers with top, bottom and side entry drive

- Customized solution

- Compact design

- Available with single- and double walled can

- High temperature version possible

- With sliding or roller bearing

SensoCan

- Additively manufactured can for magnetic couplings

- For temperature sensitive applications up to 40 bar

- Integrated hole to accommodate a temperature sensor on the can flange for condition monitoring (patented)

- Special design of the embedded channels in the can optimizes heating and cooling

- Low operating costs