EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

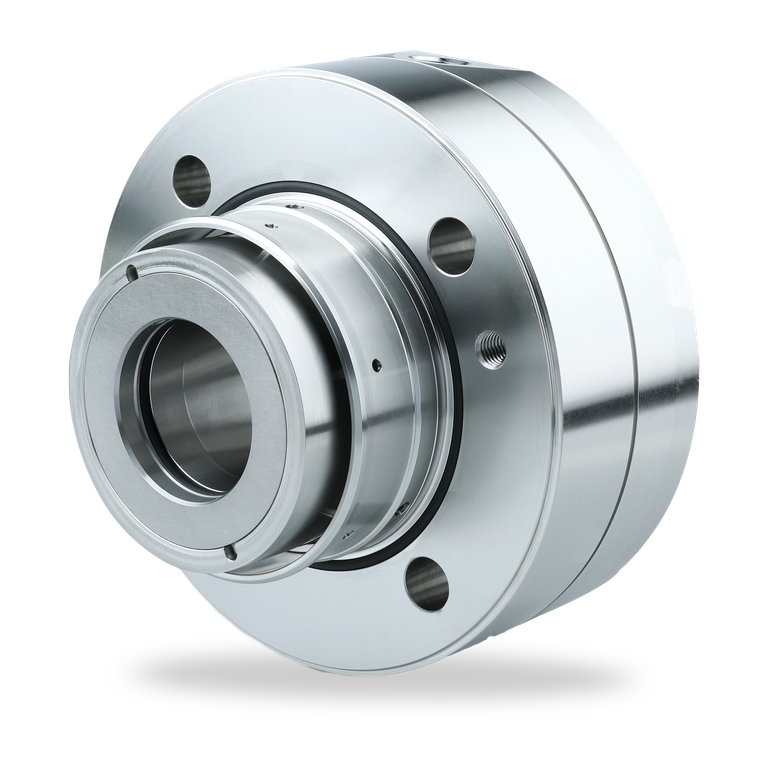

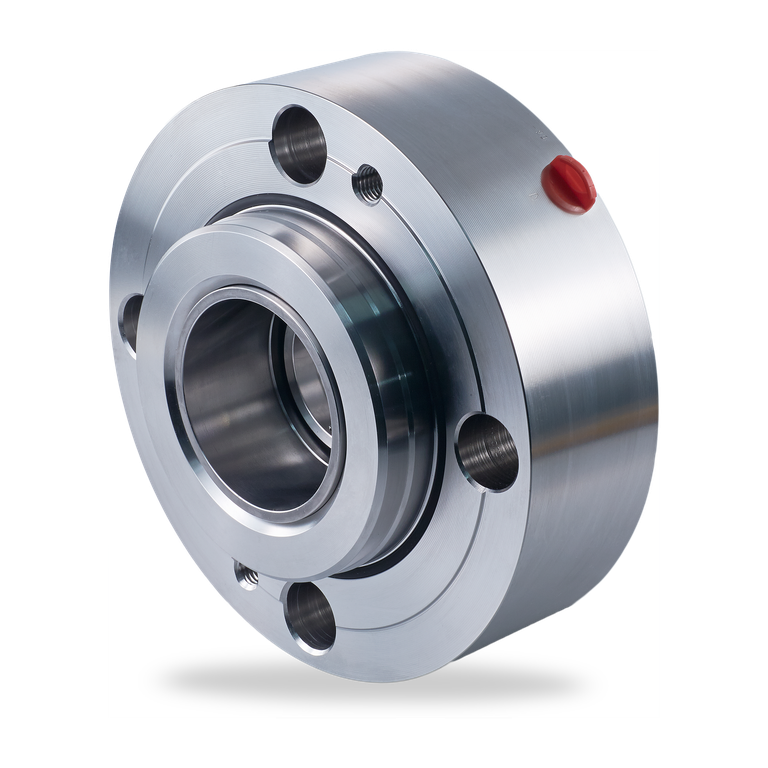

SAF(V) / SAP(V)

| Item | Description |

| 1 | Seal face |

| 2 | O-Ring |

| 3 | Spring |

| 4 | O-Ring |

| 5 | Seat collar |

| 6 | Seat |

| 7 | Shaft sleeve |

| 8 | Pumping sleeve |

| 9 | Cover |

| 10 | Throttle ring |

SAF(V) / SAP(V)

Features

- Cartridge design

- Single seal

- Balanced

- Dependent on direction of rotation

- Integrated pumping device

- Stationary spring loaded unit

- Inserted seal face

- Rotating carbon seat

Advantages

- Deformation-optimized seal for high sliding velocities and medium pressures

- Economical due to standardized inner components

- High flexibility due to adaptation of the connection parts to the pump seal chamber

- Optimum heat dissipation due to integrated pumping device and optimized seat / seal face design

- Insensitive to shaft deflections due to stationary design

- Pre-assembled unit for quick and easy installation

- Only small number of components

Operating range

d1* = 120 ... 250 mm (4.72" ... 9.84")

Pressure: p1 = 50 bar (725 PSI)

Temperature: t = +300 °C (+572 °F)

Sliding velocity: vg = 65 m/s (213 ft/s)

Axial movement: ±3 mm

* Other sizes on request

Materials

Seat: Carbon graphite resin impregnated (B),

SiC-C-Si Silicon impregnated carbon (Q3)

Secondary seals: EPDM (E), FFKM (K)

Springs: CrNiMo steel (G)

Metal parts: CrNiMo steel (G)

Recommended applications

- Power plant technology

- Oil and gas industry

- Refining technology

- Petrochemical industry

- Chemical industry

- Power generation

- Boiler feed water with low conductivity

- Boiler feed pumps

Recommended piping plans

Similar products

SHI300

- Robust seal design - suitable for demanding light hydrocarbon applications

- Compact cartridge seal - can be fitted in older pumps with small seal chambers

- Unpressurized inboard seal with a high pressure-non contacting containment seal on the outboard – fully-rated to pipeline pressure

- Stationary spring loaded unit

- Balanced primary seal faces - in materials with high thermal conductivity and strength

- Multi-point injection - uniform heat distribution

- DiamondFace® technology optional

SHI366

- Robust seal design – especially for demanding crude oil applications

- Compact cartridge seal for small seal chambers

- Single unpressurized seal with containment high-pressure throttle design

- Stationary spring loaded unit

- Balanced seal faces in materials with high thermal conductivity and strength

- Inserted seal face

- Multi-point injection of the flush fluid optional

- Seal faces can be equipped with lubrication enhancing hydropads and/or DiamondFace technology

Inquire about individual solutions

We develop and produce customer-specific special and individual solutions for every application.

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.